Designing a high quality, sustainable Industrial Corrugated Box

The general perception of an industrial package is a rudimentary cardboard shipping box with use of a single color, but that is old school. Boxes of years gone by might have fit that description, but fortunately, things have changed for the better. At Bay Cities we don’t like to put ourselves in a box (yes, the pun is intended).

Industrial boxes are meant to transport, protect, and highlight the product inside. We take great pride in the fact that our industrial packaging stands out within the corrugated packaging industry, and that your branded corrugated packaging is optimized for protection and arrives when you need it. Just because protection is the name of the game doesn’t mean you need to sacrifice creativity, opportunities for branding and using your packaging as yet, another way to connect with your customers. Whether it is the structure of a box or the graphics, there are many options for you to maintain your branding, protect your products and do this sustainably.

The concept of an industrial box may sound simple, but the reality is that it can be a challenging task.

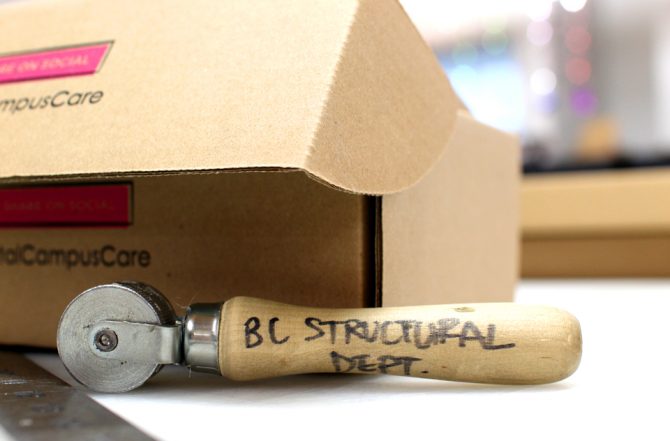

“It’s not always easy, because you can go down the wrong path from the very beginning,” said structural designer Gavin Baillie. “It is an exercise in problem solving, as you can build it the way you want and keep trying to add to it, or you can over build it and then take stuff out until it is perfect,” Baillie added.

Once given the product, our structural designers work from scratch to find the perfect mix of corrugated packaging material and printing formula. The material selection is dependent on the weight and size of the product being shipped in the box and the selected box style.

“If we are making an auto-bottom, I would not recommend using thick double wall cardboard because it would be too hard to fold the flaps necessary to glue. Heavy product will require thicker or stronger corrugated board, while designs with intricate folds work best with thin E-flute,” said structural design manager Natalie Tucker.

Our graphics team works diligently to preflight artwork to ensure that it is appropriate for packaging design and printing method.

Since industrial packaging tends to be produced on a large scale, it’s important to pay close attention to what factors may affect the sustainability of a project. By choosing the appropriate cutting process, Bay Cities can limit waste on a large scale while keeping the structural integrity of a box and saving money for all parties involved.

“I try to utilize machine run parts instead of CAD cutting or die cutting. The use of a die cutter can be wasteful in terms of economics and sustainability,” said Gavin Baillie.

Die cutting is the process of manufacturing, that uses a die board to consistently cut out the same design repeatedly, which works when you have an order for large quantities. On the other hand, CAD cutting machines trace lines of the design with a knife and create fold lines using scoring wheels. Typically, with industrial boxes like an RSC it’s faster, more cost efficient, and more sustainable to run the boxes through machines that can quickly score and slot as they print.

Stepping out of the mold of the regular slotted container, there is a world of packaging alternatives for industrial packaging that make for exciting and memorable unboxing experiences.

“If a package were a subscription box, I recommend a RETF. If it is a high-end product, the client might want a nice insert to showcase the product. If the box will be used to ship from one location to the next, we would make an RSC,” said structural design manager Natalie Tucker.

Not only do alternatives such as a RETF (roll end tuck front box) give a pleasing unboxing experience, they also align with sustainability goals. RETF boxes doesn’t require any glues or packing tape and are great for creating eco-friendly packaging.

“It is important to bear in mind that sustainability is one of our design criteria for each box. We always try to use the least amount of material as possible and fill up the entire sheet of corrugate, so less scrap is discarded. The scraps that are recycled are re-purposed into a new design in the future,” said Tucker.

When Bay Cities’ designers, are given an industrial box, it’s always a fun challenge. We ensure that companies don’t lose time and money due to poor box quality and don’t experience long lead times or late deliveries. We support their sustainability efforts, it’s our priority, when designing a custom industrial cardboard box.