Manufacture and Print

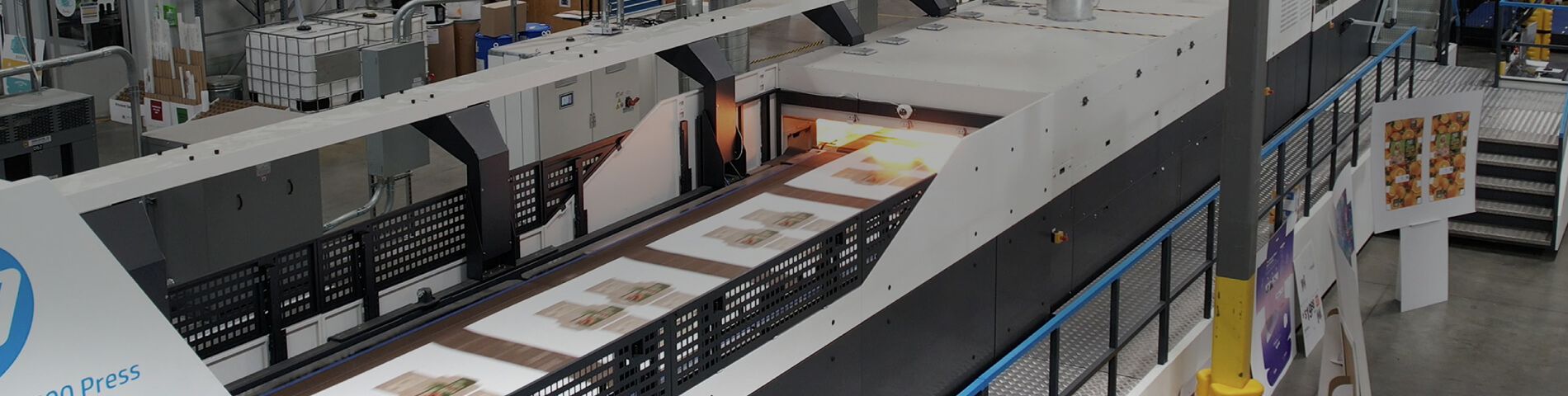

We are a one-stop shop for manufacturing, with cutting-edge technology that will help you win at retail

Our team of designers and production professionals have decades of expertise in the world of print.

Our extensive assortment of machines enable us to stay flexible and efficient, while maintaining quality. Litho, Flexo and Digital are the three main print methods used to produce your packaging and displays.